FAQ

In this section we want to help you find answers to common questions. If you do not find what you need, get in touch with us and we will be happy to help you.

What is a metal profile?

It is a product of various forms in which the cross section is constant throughout its length. They are manufactured from a steel strip without significant variation of the thickness of the source material. The profiles can have holes and be opened or closed.

What is a Profiling machine?

It is the machine that makes profiles. In the forming process, the strip is gradually bent as it passes through the rollers of the machine until the desired shape is obtained. The production rate of these machines is high, so it is used in profiles with high volume consumption.

What is tooling?

It is any object that is not a fixed part of the machine that allows the manufacture of the profile. The tooling would be the necessary for rollers to obtain the profile, the plates and blades that enable the machine to cut the steel strip, punching dies, and any other element outside of the machine itself and that is necessary to obtain the profile.

What is Strip?

It is the raw material in the form of a coil, with a defined width, thickness and material.

Types of Profiles

There are several types of profiles that can be produced with a profiling machine. On the one hand, there are the standard profiles, which can be defined by their shape, their measurements and their thickness and material.

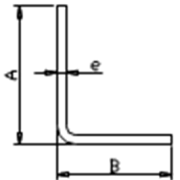

L Profile

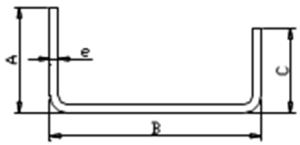

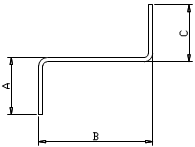

U Profile

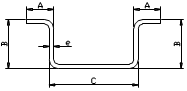

Omega Profile

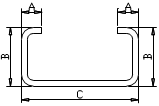

C Profile

Z Profile

On the other hand, there are special profiles, which must be made to measure under a design plan.

The standard that regulates the tolerances of the profiles is the UNE-EN 10162. It regulates the standard tolerances in the profiles formed in cold rolling process.

Types of Materials

As for materials, the most commonly used one is iron, but aluminium, stainless steel and even plastic are also cold rolled. Aluminium usually has a protective film. The most commonly used are iron, with different finishes that may be the following:

Black or hot rolled.

It’s like it comes out of the mill. It has a very abrasive oxide layer. It is very hard and black looking, which gives this material its name.

Pickling.

The steel starts out black and the oxide layer is removed with a bath. It oxidises easily, and you have to work it quickly. Normally it will have paint applied to it afterwards. It has a greyish appearance, and has thicknesses starting from 1.5 mm.

Cold.

It is cold rolled. It is done in thicknesses of up to 1.5 mm. It has a greyish appearance.

Galvanised.

It is cold or pickled material with a subsequent galvanising. The galvanised protects against corrosion. It can be star or matt. Since the star is produced by lead, matt is increasingly used.

Pre-lacquered.

It is the material that has a layer of colour in one or both parts of the strip. It is usually protected with a protective film.